You have not yet added any article to your bookmarks!

Join 10k+ people to get notified about new posts, news and tips.

Do not worry we don't spam!

Post by : Anis Farhan

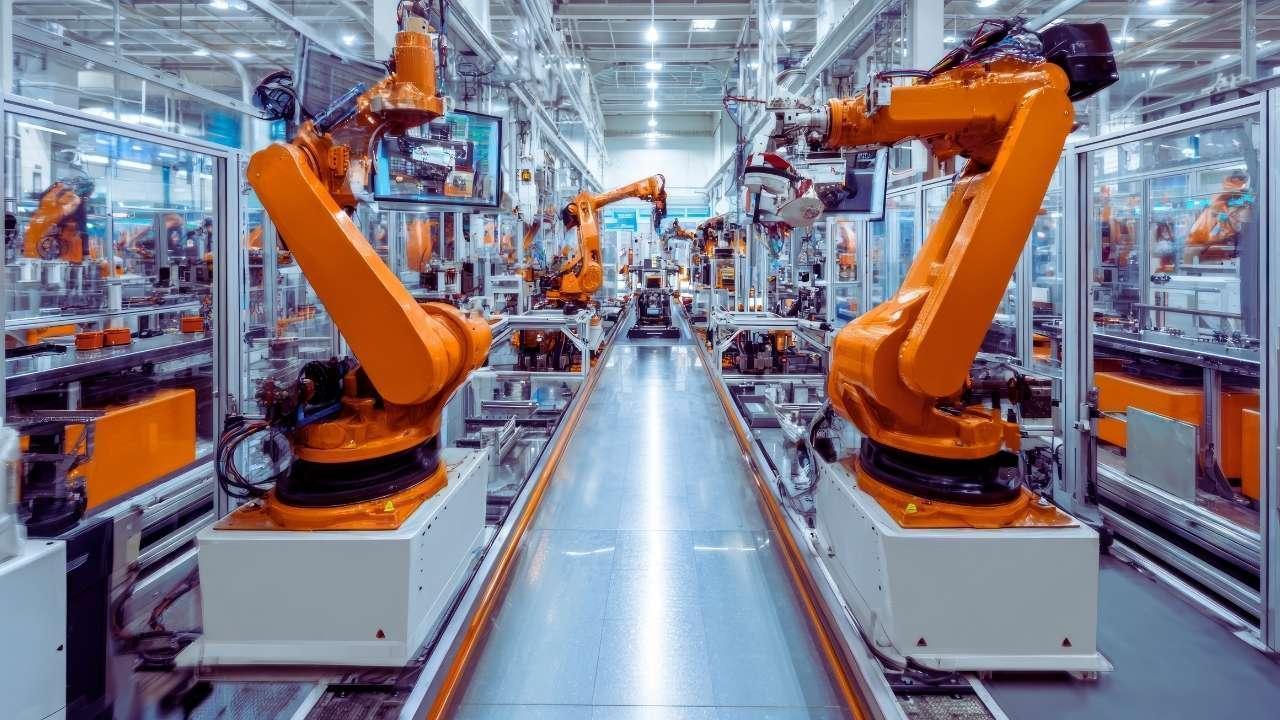

Manufacturing has long been about rigid processes, repetitive tasks, and incremental improvements. But a new wave is breaking through — generative AI. No longer just a tool to analyze data or make forecasts, generative AI is actively participating in the creation of designs, processes, systems, and even entire manufacturing lines. Factories are beginning to hand over parts of the design process to intelligent systems that generate shapes, structures, and workflows tailored to constraints, performance goals, and innovation desires.

This shift is not hypothetical; it is already occurring. Engineers feed generative models with constraints — such as material limits, weight, stress tolerances, production cost ceilings — and the system outputs multiple candidate designs, often novel and unexpected. Some of those designs go directly into prototype phase. This “machine designing machines” phenomenon is pushing the boundaries of what industrial creativity means.

Generative AI doesn’t replace human engineers; it expands them. Designers can explore more options faster, test more iterations, and shift focus toward higher‑order decision making rather than rote drafting. In short, generative AI is enabling a new synthesis of human insight and machine speed.

Several forces have converged to make generative AI practical in modern manufacturing:

Data abundance and connectivity: Sensor grids, IoT, and digital twins have produced rich datasets across machinery operation, materials behavior, supply chain performance, and production outcomes. Generative models now have the raw material to learn from.

Advancements in model architectures: Modern generative models, including diffusion methods, graph neural networks, and transformer hybrids, are better at understanding spatial, structural, and multimodal relationships.

Computational acceleration: GPUs, custom AI chips, and cloud parallelism make it possible to run generative optimization cycles in hours or minutes rather than days.

Demand for agility and efficiency: With supply chain volatility, energy constraints, and sustainability targets, manufacturers seek designs that are lighter, stronger, more efficient, and adaptable. Generative AI provides a way to squeeze new performance out of tight margins.

Strategic differentiation: Companies that embed creative AI workflows can outpace competitors in innovation speed, cost structure, and product variation.

These trends are pushing generative AI from labs and pilot projects into core industrial workflows. According to industry forecasts, the global generative AI in manufacturing market is expected to grow at a compound annual growth rate (CAGR) of about 41 % over the coming decade.

Let’s break down the main domains within manufacturing where generative AI is already making tangible impact:

One of the most celebrated applications is using AI to generate optimal shapes and forms. Given constraints (load, weight, cost, available material, manufacturing method), the AI suggests many design variants — often organic, nonintuitive, topology‑optimized forms that humans might never conceive. Engineers pick or refine among those to move forward.

The output may include CAD files ready for simulation, 3D printing or machining. This accelerates innovation and cuts design cycles significantly. Appinventiv+1

Beyond physical shapes, generative AI helps plan how parts move, which machines perform which steps, and how to balance flow. It can suggest layouts of tools, robotic arms, material transport paths, and buffering to minimize cycle times, energy use, and bottlenecks.

Factories thus evolve not only in geometry but in orchestration — the AI becomes a planner as much as creator.

By combining generative methods with forecasting, factories can simulate “what‑if” failure or wear scenarios, then generate remedial actions or maintenance schedules. Generative AI can propose replacement parts with minor tweaks to improve lifetime or reduce cost.

Generative AI can simulate supply disruptions or demand shifts and propose alternate sourcing, production redistribution, or design tweaks to mitigate risk. In effect, the design of the product and its supply ecosystem begins to co‑evolve.

In advanced domains, AI is being used to generate new material compositions or crystal structures suited for specific applications. For instance, generative models coupled with physics simulation can propose new alloys or composites optimized for strength, weight, thermal behavior, or cost.

Already, generative systems are being used to design robotic arms, end effectors, conveyor systems, or even modular machines. The next step is self‑designing factories, where generative AI proposes machines and layout, tests digital twins, and iteratively refines them — gradually shifting factories toward autonomous evolution. Some theoretical models label this as a precursor to “Industry 6.0,” where generative AI and robot swarms create products and production systems from natural language prompts.

One recent example: a desktop 5‑axis 3D printer whose structure was designed using generative AI, incorporating organic, cantilevered forms not possible via conventional methods.

It’s not just theory — companies are deploying generative AI in real factories:

Foxconn is building new AI‑powered manufacturing plants with humanoid robots and generative design in their production chain.

Consumer product lines— from shampoo bottles to home batteries — are benefiting from AI and robotics that adjust designs and operations in near real time.

A leading materials AI platform (Aethorix) has used generative AI to propose new inorganic crystal designs in just minutes, reducing development cycles dramatically.

These cases show the blending of design, automation and intelligence is not speculative — it is happening now.

Generative AI is powerful, but adopting it in manufacturing involves serious challenges:

Validation and safety: Designs from AI must be verified; unexpected stress points or real‑world behavior risks need human oversight and simulation.

Integration complexity: Generative pipelines must be integrated into CAD, PLM, simulation, manufacturing execution systems (MES) and robotics. Legacy systems resist such changes.

Data quality and bias: Generative models are only as good as the data they learn from. Biases, gaps, or noise in historical data can produce flawed outputs.

Intellectual property and explainability: Who owns an AI‑generated design? And can those designs be explained or defended legally?

Organizational and cultural friction: Engineers accustomed to control may resist handing over design steps to AI. Retraining, change management, and hybrid workflows are necessary.

Computational cost and resources: Running generative cycles — particularly for large or constrained design spaces — can demand significant compute infrastructure.

Security risk: If generative design workflows are exposed to adversarial manipulation, malicious actors might cause compromised designs or hidden flaws.

Bridging these gaps requires clear governance frameworks, human‑in‑the‑loop models, iterative validation, and gradual rollout rather than “big bang” adoption.

Generative AI in manufacturing is reshaping how talent works, how companies innovate, and how value is created:

Engineer role evolution: Designers transition from producing every sketch to curating, guiding, validating, and iterating AI outputs. Creativity shifts toward setting constraints and selecting among AI suggestions.

Faster innovation cycles: What once took weeks to design, simulate, test and iterate can shrink to days or hours with generative support.

Mass customization: Factories can offer more variants or bespoke designs at scale, because generative AI can rapidly tailor designs for customer-specific constraints.

Reduced waste and cost: Optimized designs use less material, require fewer prototypes, lower energy consumption, and reduce failure risk — improving margins.

New product paradigms: Companies may compete by design agility and adaptability rather than just scale or cost. Generative AI becomes a differentiator.

Business models may shift toward service models: offering design‑as‑a‑service, generative design platforms, or modular subscription models.

For manufacturing leaders seeking to adopt generative AI, here’s a practical roadmap:

Start small with pilot projects

Choose low-risk components or subsystems and run generative design pilots to validate workflow, integration, and ROI.

Build a generative design infrastructure

Invest in computing power (GPU / AI hardware), CAD/PLM integration, simulation tools, version control, and team tooling.

Ensure data readiness

Clean, annotate, standardize historical data and simulation results, material properties, failure records, and domain constraints.

Adopt human‑in‑the‑loop workflows

Let experts review, filter, refine AI outputs in the early stage — maintaining trust and safety while learning capabilities.

Measure and iterate

Track metrics such as design cycle time, cost savings, performance gains, error rates, and adoption. Use those insights to iterate.

Governance and IP policies

Define ownership, auditing, traceability, explainability, compliance and legal boundaries early, especially when generative outputs feed into production.

Scale gradually across systems

Once confidence builds with core components, expand generative design to workflows, processes, robotics layouts, and maybe full machines.

Culture shift and training

Train engineers to think in constraint-based, parametric, and generative mindsets rather than traditional drafting. Encourage collaboration between AI experts and domain engineers.

The horizon is bold. As generative AI, robotics, and digital twins mature, fully autonomous factories may become feasible. Imagine describing a new product goal in natural language, and a system proposes designs, production workflows, robotic layouts, material sourcing, and deployment — all autonomously refined and validated. That is the vision behind “Industry 6.0,” where human direction sets goals, and machines handle the creative and operational steps.

Robotic swarms, again designed and optimized by AI, could self‑configure, self‑repair, and self‑evolve. Generative AI may even engage in competitive co‑design, balancing constraints across business units, sustainability goals, and supply chain dynamics.

In material science, generative models will push new frontier compounds, metamaterials, and composite structures with unprecedented properties, transforming how machines are built.

Generative AI will not replace human ingenuity; it will partner with it — driving a new era of industrial creativity, agility and resilience.Conclusion: A New Industrial Paradigm

Generative AI in manufacturing is more than incremental automation — it’s a paradigm shift. From designing parts to orchestrating whole factories, from materials innovation to process layout, machines are now both tool and collaborator in creation. The factories of tomorrow will think, adapt and design — not just execute.

The journey is not without challenges: validation, data, trust, integration, and cultural adoption are serious obstacles. But those who navigate them early will secure a competitive edge in speed, sustainability, customization, and innovation.

The future of manufacturing lies in machines designing machines — a symbiosis of human vision and generative intelligence. That future is arriving now.

This article is provided for informational and illustrative purposes. It does not represent the position of any specific company. Before adopting generative AI in manufacturing workflows, organizations should conduct independent technical and legal evaluations, and consult with domain experts.

Akshaye Khanna exits Drishyam 3; Jaideep Ahlawat steps in fast

Producer confirms Jaideep Ahlawat replaces Akshaye Khanna in Drishyam 3 after actor’s sudden exit ov

Kapil Sharma’s Kis Kisko Pyaar Karoon 2 to Re-release in January 2026

After limited screens affected its run, Kapil Sharma’s comedy film Kis Kisko Pyaar Karoon 2 will ret

Hrithik Roshan and Saba Azad Celebrate Christmas at Family Party

Hrithik Roshan and Saba Azad celebrated Christmas at Sussanne Khan’s party, sharing happy moments wi

China Sanctions 20 US Defense Firms Over Taiwan Arms Sales Dispute

China imposes sanctions on 20 US defense companies and 10 executives for supplying arms to Taiwan, e

Salman Khan’s Grand 60th Birthday Bash at Panvel Farmhouse Shines Bright

Salman Khan celebrates his 60th birthday with a grand party at Panvel farmhouse, sharing joyful mome

Thailand Defence Minister Joins Talks to End Deadly Border Clash

Thailand’s defence chief will join talks with Cambodia as border clashes stretch into a third week,