You have not yet added any article to your bookmarks!

Join 10k+ people to get notified about new posts, news and tips.

Do not worry we don't spam!

Post by : Samjeet Ariff

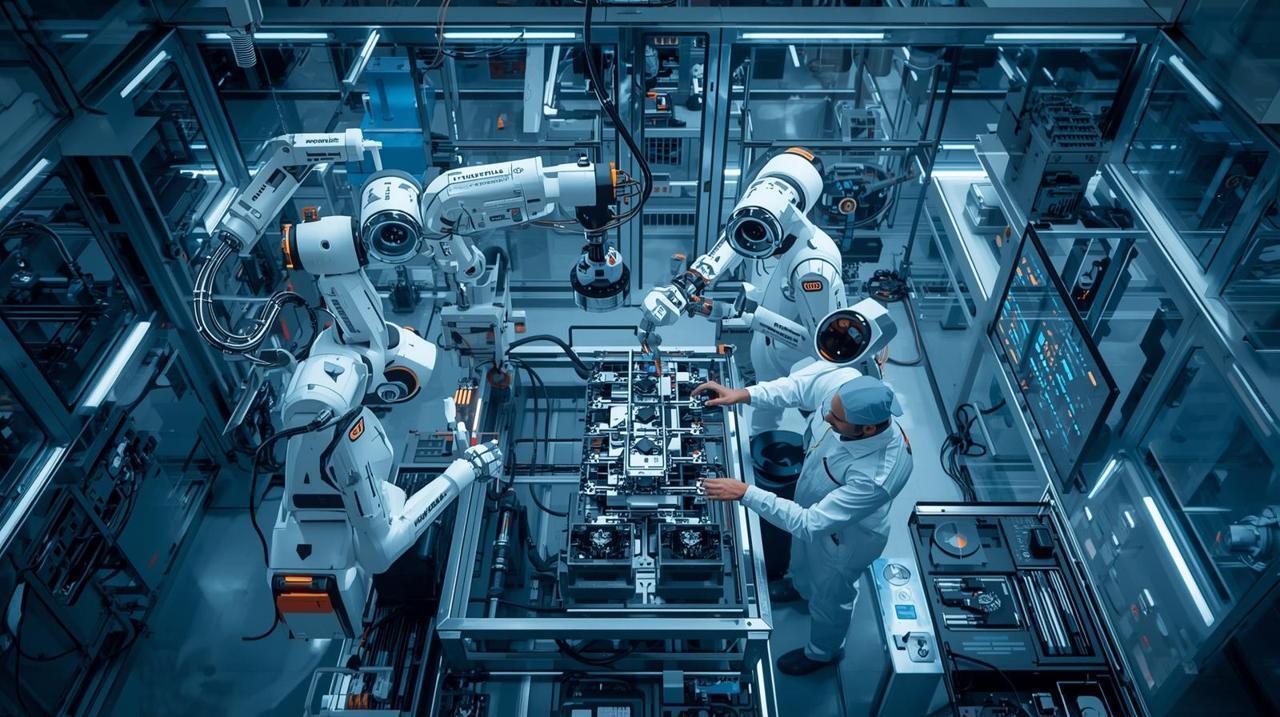

Manufacturing is undergoing a major shift as Artificial Intelligence (AI) and robotic systems move beyond simple automation. Plants that once relied on manual labour and fixed machinery are evolving into connected, responsive, and more productive operations.

From digitised production lines and to collaborative machines that partner with people, the combined effect of AI and robotics is remaking how products are conceived, manufactured and delivered. This transformation is not merely incremental—it represents a structural change in the industrial model.

Where older factories optimised through scale, modern facilities pursue efficiency through intelligence. AI-driven analytics, machine learning and robotic automation enable real-time, data-informed choices across the shop floor. This integrated approach is central to Industry 4.0, the movement linking machines, people and data into a single system.

Robots are no longer limited to repetitive, caged tasks. Today’s machines are more adaptable, perceptive and safe to work alongside human employees.

Cobots are engineered to collaborate directly with operators rather than operate behind safety barriers.

They perform precision work such as welding, inspection and packing.

They are simple to reprogram for different tasks.

They help lower mistakes and speed up output.

Vendors like ABB, KUKA, and Universal Robots are expanding access to cobots so smaller manufacturers can adopt them affordably.

AMRs driven by AI are transforming logistics and material handling. Using cameras and sensors, these mobile units navigate warehouse floors, transport items and avoid hazards autonomously.

They decrease manual handling needs and enhance safety and throughput—especially in large-scale distribution centres such as those run by Amazon.

If robots provide the hands of modern manufacturing, AI supplies the decision-making. Machine intelligence digests vast production datasets to reveal inefficiencies, anticipate failures and fine-tune operations.

AI enables predictive maintenance by using sensor data and analytics to identify potential equipment faults before they occur.

This approach cuts costly stoppages.

It allows maintenance to be scheduled proactively.

It prolongs machinery life cycles.

Industry studies, including McKinsey research, suggest AI-based predictive maintenance can trim maintenance spending by around 25% and reduce unexpected breakdowns by up to 70%.

AI-enhanced computer vision systems are improving quality checks. Automated inspection can spot minute defects invisible to humans, ensuring products consistently meet specifications.

Sectors such as semiconductors, automotive and pharmaceuticals increasingly depend on these tools to maintain standards and prevent costly recalls.

AI also delivers end-to-end visibility across supply chains. Advanced models help companies:

Forecast demand more reliably.

Automate inventory adjustments.

Plan more efficient delivery routes.

These capabilities reduce waste, speed deliveries and lower costs—building greater resilience into global supply chains.

Automation is expanding, but human skills remain central. The future emphasises augmentation rather than wholesale replacement.

Robots and AI take on repetitive or hazardous duties, freeing humans for creative problem-solving, oversight and complex decision-making. Firms that invest in reskilling and AI-based training see gains in productivity and innovation.

Every connected device on a modern shop floor generates streams of information—often terabytes daily. AI converts this raw data into operational insight, enabling instant adjustments.

Intelligent factories use these feeds to:

Auto-adjust production timetables.

Identify bottlenecks.

Lower energy consumption.

As data volumes grow, systems become more adaptive, creating continuous performance improvements.

The fusion of 3D printing and AI is another disruptive force. Algorithms optimise designs for additive manufacturing, producing components that are lighter, stronger and more cost-effective.

Fields like aerospace, automotive and healthcare use this pairing to produce bespoke parts rapidly with far less material waste than conventional methods.

AI and robotics also support greener manufacturing. Connected plants can:

Cut energy use through intelligent monitoring.

Minimise material waste via precision robotics.

Reduce emissions by optimising logistics.

For instance, Siemens employs AI for energy management across its sites, demonstrating that enhanced efficiency and lower carbon footprints can go together.

Significant hurdles remain:

High upfront investment that can deter smaller firms.

Increased cybersecurity exposure as systems connect.

Concerns about job displacement caused by automation.

Shortages of skills in AI, data science and robotics upkeep.

Addressing these issues requires public-private collaboration and targeted upskilling programs to make the transition inclusive.

Nations such as Germany, Japan, South Korea and China are at the forefront of smart manufacturing. Governments in places like India and the UAE are also promoting Industry 4.0 policies to attract technology-led investment.

Manufacturers including Tesla, Foxconn and Bosch illustrate how automation and AI can scale production while preserving quality.

Market analysts forecast the smart manufacturing sector could top $800 billion by 2030, propelled by continued AI and automation adoption.

The long-term outlook points to increasingly autonomous plants—operations where AI orchestrates production with minimal human intervention.

Envision scenarios where:

Production adapts automatically to demand forecasts.

Robots complete assembly, inspection and packaging seamlessly.

AI systems negotiate procurement and logistics in real time.

Advances in AI, robotics, IoT and 5G are bringing that vision closer to reality.

The pairing of AI and robotics is redefining manufacturing: factories are becoming smarter, safer and more efficient, delivering higher-quality goods with lower environmental impact.

Although costs and workforce training pose challenges, the advantages—from enhanced productivity to sustainability—are compelling.

As AI-driven smart factories scale, they will not only produce items more efficiently but also reshape competitive advantage across industries.

The manufacturing revolution is underway—powered by intelligence, automation and connectivity.

Thailand Defence Minister Joins Talks to End Deadly Border Clash

Thailand’s defence chief will join talks with Cambodia as border clashes stretch into a third week,

India Raises Alarm Over Fresh Attacks on Hindus in Bangladesh

India has condemned recent killings of Hindu men in Bangladesh, calling repeated attacks on minoriti

Sidharth Malhotra & Kiara Advani Celebrate Baby Saraayah’s 1st Christmas

Sidharth and Kiara share adorable moments of baby Saraayah’s first Christmas with festive décor and

South Korea Seeks 10-Year Jail Term for Former President Yoon Suk Yeol

South Korea’s special prosecutor demands 10 years for ex-President Yoon Suk Yeol on charges includin

Salman Khan’s Exclusive 60th Birthday Bash at Panvel Farmhouse

Salman Khan to celebrate his 60th birthday privately at Panvel farmhouse with family, friends, and a

Dhurandhar Breaks Records with Rs 1006 Cr, Becomes Bollywood’s Biggest Hit

Dhurandhar rakes in over Rs 1006 crore worldwide in 21 days, becoming Bollywood’s highest-grossing f